Icandelo 2. Itekhnoloji: i-aluminium extrusion + i-friction ivuselela i-welding njengeyona nto iphambili, i-laser welding kunye ne-FDS okanye ibe ngulwalathiso lwexesha elizayo.

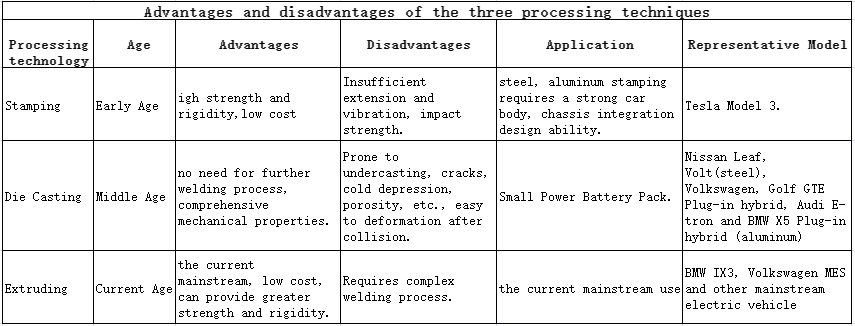

1. Xa kuthelekiswa ne-die casting kunye nesitampu, i-aluminium extrusion eyenza iiprofayili kwaye emva koko i-welding yiteknoloji eqhelekileyo yeebhokisi zebhetri okwangoku.

1) Ubunzulu bomzobo weqokobhe phantsi kwepakethi yebhetri edityaniswe yipleyiti ye-aluminiyam, ukungcangcazela okungonelanga kunye namandla empembelelo yebhetri yepakethe, kunye nezinye iingxaki zifuna ukuba amashishini emoto abe nesakhono soyilo esiluqilima esidityanisiweyo somzimba kunye ne-chassis;

2) Itreyi yebhetri ye-aluminium yokuphosa kwimowudi yokuphosa ithatha ukubumba ixesha elinye. Ukungalungi kukuba i-alloy ye-aluminium ixhomekeke kwi-undercasting, i-cracks, i-cold isolation, ukudakumba, i-porosity kunye nezinye iziphene kwinkqubo yokuphosa. Ipropati yokutywinwa kwemveliso emva kokuphosa ihlwempu, kwaye ukunyuswa kwe-alloy aluminium alloy iphantsi, ejongene nokuguqulwa emva kokungqubana;

I-3) I-aluminiyam eyongeziweyo ye-alloy yebhetri ye-tray yinkqubo yangoku yoyilo lwe-tray yebhetri, ngokudibanisa kunye nokulungiswa kweeprofayili ukuhlangabezana neemfuno ezahlukeneyo, ineenzuzo zoyilo oluguquguqukayo, ukuqhutyelwa phambili, kulula ukuyiguqula njalo njalo; Ukusebenza I-extruded aluminium alloy battery tray inokuqina okuphezulu, ukuxhathisa ukungcangcazela, i-extrusion kunye nokusebenza kwempembelelo.

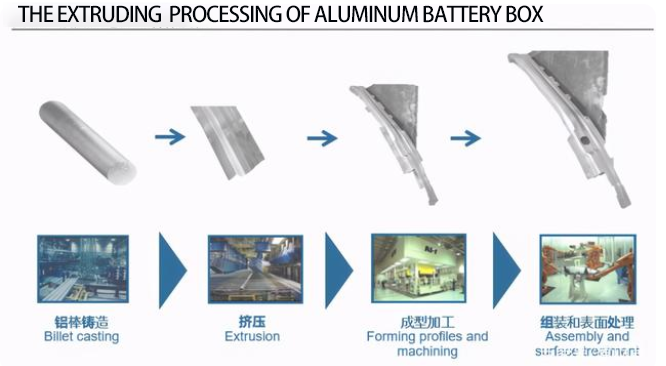

2. Ngokukodwa, inkqubo ye-aluminium extrusion ukwenza ibhokisi yebhetri ngolu hlobo lulandelayo:

Ipleyiti engezantsi yebhokisi yebhokisi yenziwe ngokuxutyushwa kwe-friction ye-welding emva kokuba ibha ye-aluminium ikhutshiwe, kwaye umzimba webhokisi ongezantsi wenziwa nge-welding kunye neepleyiti ezine zecala. Okwangoku, iprofayili eqhelekileyo ye-aluminium isebenzisa i-6063 okanye i-6016 eqhelekileyo, amandla okuqina aphakathi kwe-220 ~ 240MPa, ukuba ukusetyenziswa kwamandla aphezulu e-aluminium ekhutshiweyo, amandla okuqina anokufikelela ngaphezu kwe-400MPa, xa kuthelekiswa nebhokisi yeprofayili ye-aluminium eqhelekileyo inokunciphisa ubunzima ngama-20% ~ 30%.

3. Itekhnoloji ye-Welding iphinda iphuculwe ngokuqhubekayo, eyona nto ikhoyo ngoku yi-friction stir welding

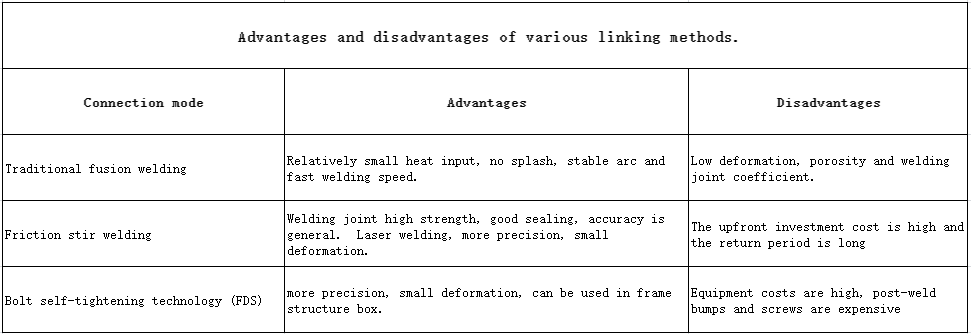

Ngenxa yesidingo sokudibanisa iprofayili, iteknoloji ye-welding inempembelelo enkulu kwi-flatness kunye nokuchaneka kwebhokisi yebhetri. Itekhnoloji ye-welding yebhokisi yebhetri yahlulwe kwi-welding yendabuko (i-TIG ye-welding, i-CMT), kwaye ngoku i-welding ye-friction ehamba phambili (i-FSW), i-laser welding ephezulu, i-bolt self-tightening technology (FDS) kunye nobuchwepheshe bokudibanisa.

Ukuwelda kwe-TIG kuphantsi kokhuseleko lwegesi engasebenziyo, kusetyenziswa i-arc eyenziwe phakathi kwe-electrode ye-tungsten kunye ne-weldment ukutshisa isiseko sesinyithi esinyibilikayo kunye nokuzalisa ucingo, ukuze zenze i-welds ezikumgangatho ophezulu. Nangona kunjalo, ngokuziphendukela kwesakhiwo sebhokisi, ubungakanani bebhokisi buba bukhulu, isakhiwo seprofayili siya kuba sincinci, kwaye ukuchaneka kwe-dimensional emva kwe-welding kuphuculwe, i-TIG ye-welding ikwimeko engalunganga.

I-CMT yinkqubo ye-welding entsha ye-MIG / MAG, usebenzisa i-pulse enkulu yangoku ukwenza i-arc ye-welding wire ngokufanelekileyo, ngokusebenzisa i-tension surface surface, i-gravity kunye ne-mechanical pumping, ukwenza i-weld eqhubekayo, kunye ne-input encinci yokushisa, akukho splash, i-arc ukuzinza kunye nesantya se-welding ekhawulezayo kunye nezinye iingenelo, zingasetyenziselwa iintlobo ezahlukeneyo ze-welding. Ngokomzekelo, isakhiwo sebhokisi phantsi kwephakheji yebhetri esetyenziswa yi-BYD kunye ne-BAIC iimodeli ezininzi zamkela iteknoloji ye-CMT ye-welding.

4. I-welding ye-fusion yendabuko ineengxaki ezifana ne-deformation, i-porosity kunye ne-welding ephantsi ye-coefficient edibeneyo ebangelwa igalelo elikhulu lokushisa. Ke ngoko, itekhnoloji ye-welding esebenzayo ngakumbi kunye neyohlaza ivuselela itekhnoloji enomgangatho ophezulu wokuwelda isetyenziswe ngokubanzi.

I-FSW isekwe kubushushu obuveliswa kukungqubana phakathi kwenaliti yokuxuba ejikelezayo kunye negxalaba le-shaft kunye nesiseko sesinyithi njengomthombo wobushushu, ngokujikeleza kwenaliti yokuxuba kunye ne-axial force yegxalaba le-shaft ukufezekisa ukuhamba kweplastiki yesiseko sesinyithi ukufumana i-welding joint. Ukudibanisa i-FSW kunye namandla aphezulu kunye nokusebenza kakuhle kokutywinwa kusetyenziswa ngokubanzi kwintsimi yebhokisi yebhokisi yebhetri. Umzekelo, ibhokisi yebhetri yeemodeli ezininzi ze-Geely kunye ne-Xiaopeng zamkela ulwakhiwo lwe-welding enamacala amabini.

I-laser welding isebenzisa i-laser beam ene-energy high density to irradiate the surface of the material to be welded ukunyibilikisa izinto kunye nokwenza i-joint ethembekileyo. Izixhobo ze-laser welding azizange zisetyenziswe ngokubanzi ngenxa yeendleko eziphezulu zotyalo-mali lokuqala, ixesha elide lokubuya, kunye nobunzima be-aluminium alloy laser welding.

5. Ukuze kuncitshiswe impembelelo ye-welding deformation ekuchanekeni kobungakanani bebhokisi, i-bolt self-tightening technology (FDS) kunye ne-bonding technology iqaliswa, phakathi kwayo amashishini awaziwayo yi-WEBER eJamani kunye ne-3M e-United States.

Itekhnoloji yoqhagamshelo lwe-FDS luhlobo lwenkqubo ebandayo yokwenza i-self-tapping screw kunye noqhagamshelo lwebholiti ngokuqiniswa kweshafti yeziko lezixhobo ukuqhuba ukujikeleza ngesantya esiphezulu semoto ukuze kudityaniswe nobushushu bentsimbi yepleyiti kunye noguquko lweplastiki. Ngokuqhelekileyo isetyenziselwa iirobhothi kwaye inezinga eliphezulu lokuzenzekelayo.

Kwintsimi yokuvelisa ibhetri entsha yamandla, inkqubo isetyenziswe ngokukodwa kwibhokisi yesakhiwo sesakhelo, kunye nenkqubo yokudibanisa, ukwenzela ukuba kuqinisekiswe amandla okudibanisa okwaneleyo ngelixa uqonda ukusebenza kokutywinwa kwebhokisi. Ngokomzekelo, ibhetri yemoto ye-NIO isebenzisa iteknoloji ye-FDS kwaye iye yaveliswa ngokobungakanani. Nangona iteknoloji ye-FDS ineenzuzo ezicacileyo, nayo ineziphene: iindleko eziphezulu zezixhobo, iindleko eziphezulu ze-post-weld protrusions kunye nezikrufu, njl., kunye neemeko zokusebenza zinciphisa ukusetyenziswa kwayo.

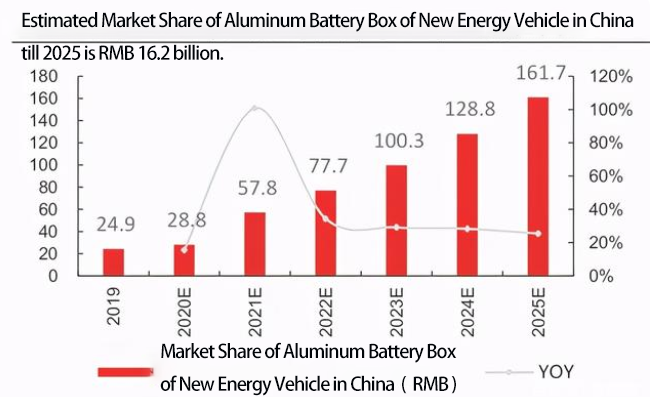

Icandelo 3. Isabelo seMakethi: indawo yemarike yebhokisi yebhetri inkulu, kunye nokukhula ngokukhawuleza

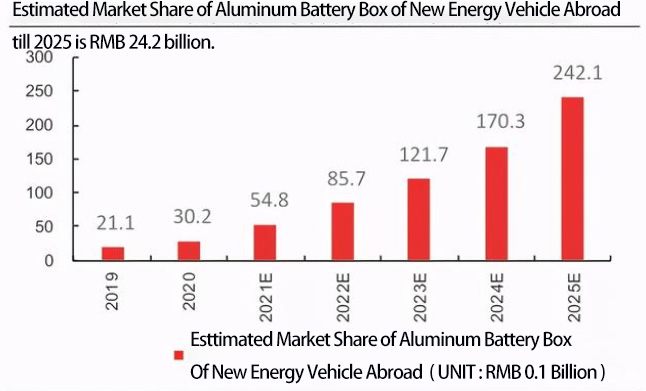

Izithuthi zombane ezicocekileyo ziyaqhubeka nokunyuka kumthamo, kwaye indawo yemarike yeebhokisi zebhetri yezithuthi zamandla amatsha zanda ngokukhawuleza. Ngokusekwe kuthelekelelo lwentengiso yasekhaya neyehlabathi yezithuthi zamandla amatsha, sibala isithuba semalike yasekhaya yeebhokisi zebhetri yemoto entsha ngokuthatha umndilili wexabiso leyunithi nganye yeebhokisi zebhetri zamandla amatsha:

Iingqikelelo ezingundoqo:

1) Umthamo wokuthengisa wezithuthi zamandla amatsha eTshayina ngo-2020 yi-1.25 yezigidi. Ngokutsho kweSicwangciso esiPhakathi kunye nexesha elide loPhuhliso lwe-Automobile Industry ekhutshwe yiMinistries emithathu kunye neekomishini, kunengqiqo ukucinga ukuba umthamo wokuthengiswa kwezithuthi zamandla amatsha abakhweli e-China ngo-2025 uya kufikelela kwi-6.34 yezigidi, kunye nokuveliswa kwamanye amazwe kwezithuthi zamandla amatsha kuya kufikelela kwi-8.07 yezigidi.

I-2) Umthamo wokuthengisa wasekhaya wezithuthi zombane ezicocekileyo uthatha i-77% ngo-2020, ucinga ukuba umthamo wokuthengisa uya kubalelwa kwi-85% ngo-2025.

I-3) I-permeability yebhokisi ye-aluminium alloy ibhetri kunye ne-bracket igcinwe kwi-100%, kwaye ixabiso lebhayisikili enye yi-RMB3000.

Iziphumo zokubala: kuqikelelwa ukuba ngo-2025, indawo yemarike yeebhokisi zebhetri yezithuthi zabagibeli zamandla amatsha e-China nakwamanye amazwe ziya kuba malunga ne-RMB 16.2 yezigidigidi kunye ne-RMB 24.2 yeebhiliyoni, kwaye izinga lokukhula kwe-compound ukusuka kwi-2020 ukuya kwi-2025 liya kuba yi-41.2% kunye ne-51.7%

Ixesha lokuposa: May-16-2022