Xa ujonge ukusombulula iimfuno zoyilo lwemveliso yakho kunye nezisombululo zealuminiyam eyongeziweyo, kuya kufuneka kwakhona ufumanise ukuba loluphi uluhlu lomsindo olulungele iimfuno zakho. Ke, unolwazi olungakanani malunga nobushushu be-aluminium? Nasi isikhokelo esikhawulezayo sokukunceda.

Ziziphi iimpawu zomsindo we-aluminium alloy?

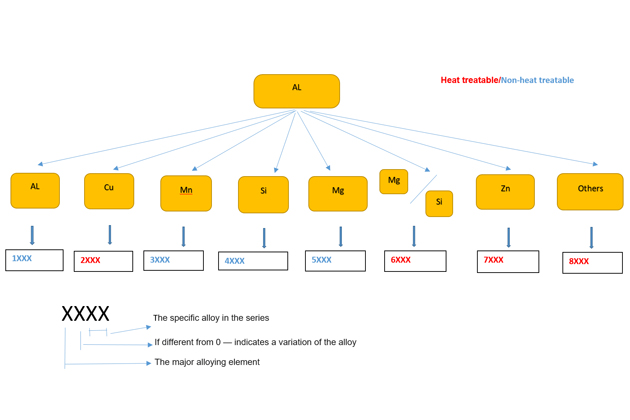

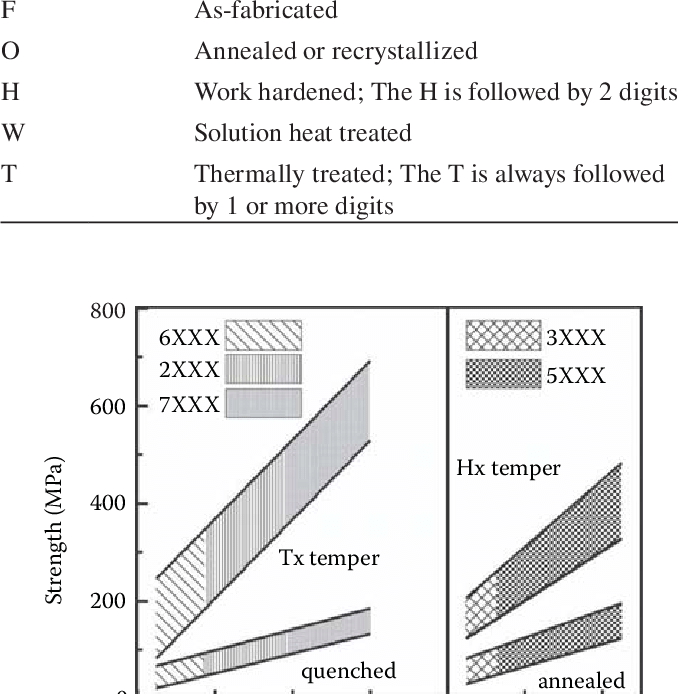

Ukutyunjwa kombuso kubonisa utshintsho kwiipropati ezibonakalayo ezinokufumaneka kwi-alloy. I-alloys esizikhuphayo, ezifana ne-alloys ekhandiweyo ye-aluminiyam, zohlulwe zibe ziindidi ezimbini: ziyanyangeka ubushushu kunye nezinganyangekiyo ngenxa yobushushu. I-1xxx, 3xxx kunye ne-5xxx series ayinyangeki ubushushu, ngelixa i-2xxx, i-6xxx kunye ne-7xxx series zinyangeka ngobushushu. Uluhlu lwe-4xxx luqulethe zombini iindidi. I-alloys enganyangekiyo ekushiseni ayinakomelezwa kakhulu ngonyango lobushushu kwaye endaweni yoko ixhomekeke kwiqondo lokusebenza okubandayo ukuphucula iipropati zabo. Ngakolunye uhlangothi, ii-alloys eziphathwa ngobushushu, zinokuqiniswa ngonyango lobushushu. Ezi zintlukwano kwi-chemical and metallurgical structure nazo zichaphazela indlela i-alloy esabela ngayo ngexesha le-welding kunye nezinye iinkqubo zokuvelisa. Ngokusisiseko, uluhlu olubanzi lweealloyi ze-aluminium kunye namazwe ashushu enza usapho oluntsonkothileyo lwezixhobo, kwaye ukuqonda lo mahluko usisiseko kunokukhokelela kwimpumelelo enkulu.

Iintlobo ezintlanu zomsindo we-aluminium alloy

Ukuqonda ukutyunjwa kwemeko kubalulekile ekuqondeni iipropati kunye nohlobo lweemveliso ze-aluminium. Ezi zibizo ziyi-alphanumeric kwaye zongezwa kwigama le-alloy ukubonelela ngolwazi malunga nendlela i-alloy ephathwa ngayo ngomatshini kunye / okanye iphathwa nge-thermal ukufumana iipropati ezifunwayo. Ngokomzekelo, i-6061-T6 imele igama elithile lesimo. Unobumba wokuqala kwigama lomsindo (F, O, H, W, okanye T) ubonisa udidi lokuphatha ngokubanzi.

Iimveliso ze-F-state ziimveliso ezigqityiweyo ezifuna ukuqhubekekiswa ngakumbi ukufumana imilo egqityiweyo okanye imeko.

I-O ibonisa iimveliso ezifakwe kwi-anneal ukunyusa ukusebenza okanye ukwandisa ukuqina kunye ne-ductility.

H imele ingxubevange enganyangekiyo enganyangekiyo.

I-W ifanelekile kwii-alloys ezikhulile ngokwendalo emva kokulungiswa kobushushu besisombululo.

I-T ibhekisa kuhlobo lwemveliso yayo nayiphi na ingxubevange enyangwa ngobushushu ethe yanyangwa ubushushu, yacinywa, kwaye yandala. Ukuqaphela kunye nokuqonda le meko kutyunjwa kubalulekile kubavelisi kunye nabasebenzisi ukuba baqonde imbali yokucubungula kunye neempawu zeemveliso ze-aluminium.

Indlela umsindo oyichaphazela ngayo imveliso yakho

Abasebenzisi bokugqibela kufuneka baqonde olu bizo ngokweenkcukacha ukunqanda ukubeka esichengeni ukusebenza okubalulekileyo okunikezwe ngumenzi kamva kwinkqubo. Umzekelo, ukulungelelanisa iipropathi zomatshini we-alloy ephathwa ngobushushu kufuna ukukhetha isisombululo esifanelekileyo sonyango lobushushu, izinga lokucima, kunye nokulandelelana konyango lokuguga. Oku kunokonyusa ukunganyangeki komhlwa ngeendleko zamandla. Ukongezelela, ukufudumala kwe-alloy kunokuchaphazela ukubonakala kwemveliso emva kwe-anodization ngenxa yokusabela kwe-alloy kwinkqubo. Ukuqonda ii-alloys ezahlukeneyo ze-aluminium kunye namazwe kunye neempawu zomatshini abanikezela ngazo kunokuba ngumngeni, ngakumbi kwiinjineli zezakhiwo eziqhele ukusebenza ngentsimbi. Nangona kunjalo, ibalulekile, kwaye ndiyathemba ukuba esi sikhokelo sikhawulezayo malunga nokutyunjwa komsindo linyathelo eliya kwicala elifanelekileyo.

Ukuba ufuna ukwazi ngakumbi, okanye unemibuzo, zive ukhululekileQhagamshelana nathi!

Tel/WhatsApp: +86 17688923299 E-mail: aisling.huang@aluminum-artist.com

Ixesha lokuposa: Jul-05-2024