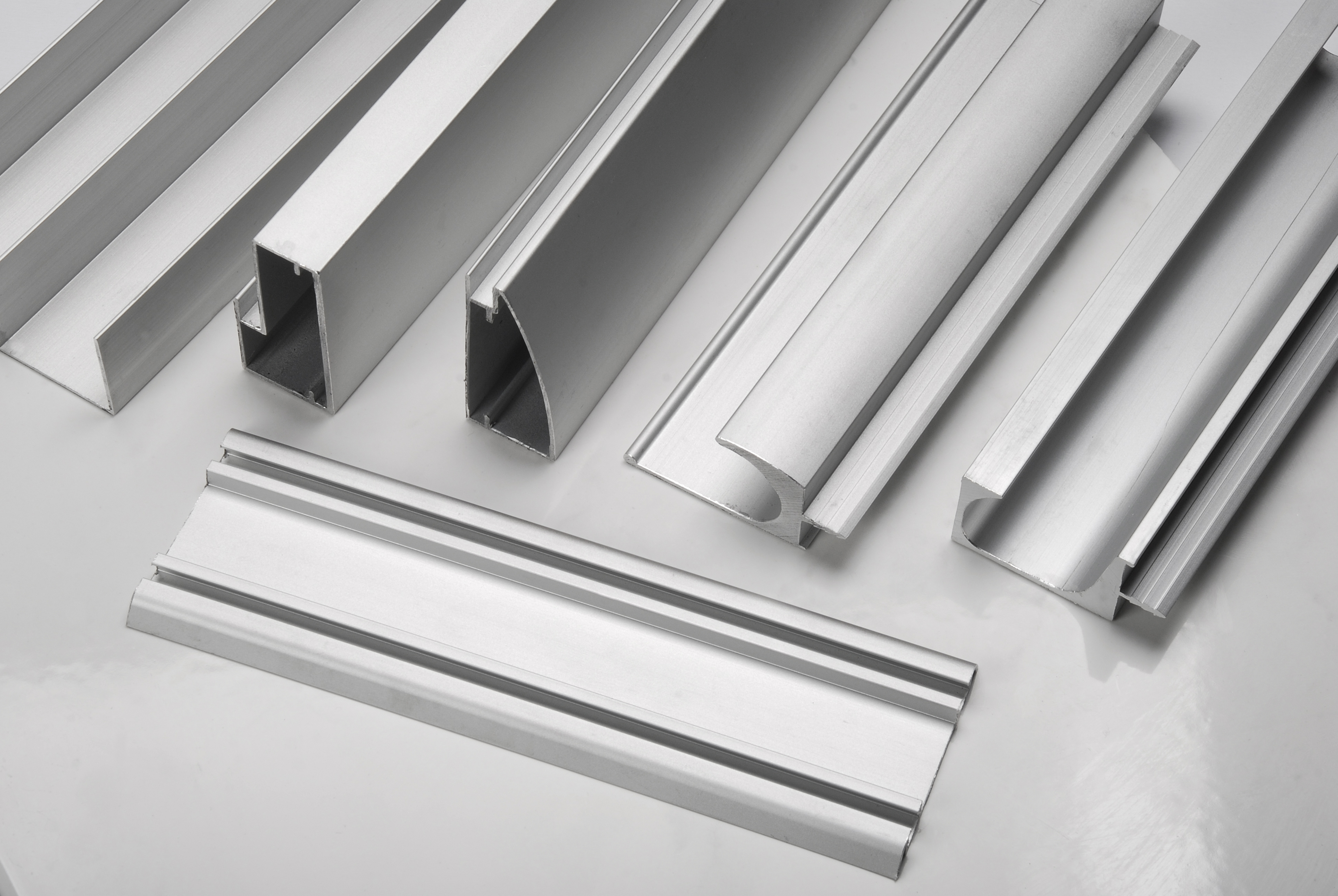

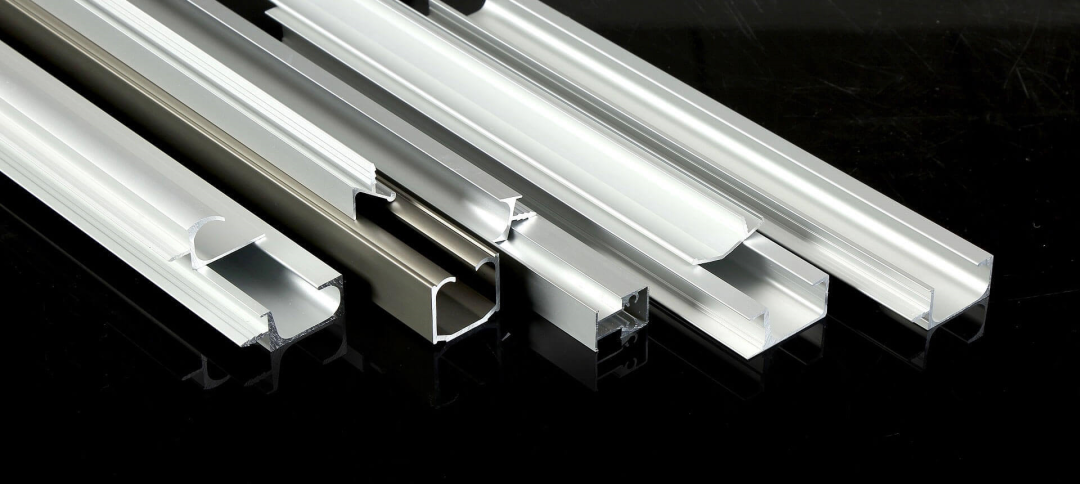

I-Aluminiyam yinto ebalulekileyo esisiseko. Kubomi bemihla ngemihla, sinokubona ukusetyenziswa kweeprofayili ze-aluminium ekwakheni iingcango,iifestile, iindonga zamakhethini, imihlobiso yangaphakathi nangaphandle kunye nezakhiwo zokwakha.

Iiprofayili ze-architectural aluminiyam zineemfuno ezithile zokulinganisa kunye nokuveliswa kobuninzi, kwaye inkqubo ye-aluminium rod extrusion idla ngokusetyenziselwa ukufikelela kwisisombululo esilungisiweyo sokuvelisa kunye nokuvelisa. Ingcamango esisiseko ye-aluminiyam yeprofayili extrusion kukusebenzisa uxinzelelo oluthile kwintonga ye-aluminiyam kwi-barrel ye-extrusion ukwenza i-alloy ye-aluminium iphume kumngxuma othile wokufa, ngaloo ndlela ifumana iiprofayili ze-aluminium zeemilo ezithile kunye nobukhulu. Le ndlela yokucubungula i-extrusion inexabiso eliphantsi, ukusebenza kakuhle okuphezulu kunye nokusebenza okulula, kwaye ithatha indawo enkulu kwinkqubo yemveliso yanamhlanje. Eli nqaku liza kugxila kwinkqubo yokuveliswa kweprofayili ye-aluminium, evumela ukuba sibe nokuqonda okunzulu kweemveliso zeprofayili ye-aluminium:

1. Ukuveliswa kwemathiriyeli ekrwada

Ngokutsho komlinganiselo obaliweyo wokwakheka kweeprofayili ezifunekayo ze-aluminium, izixhobo ezahlukeneyo eziluhlaza zixhotyiswe ngokufanelekileyo.I-ingot ye-aluminium ifudunyezwe kwiqondo elithile lobushushu lokunyibilika, kunye nomlinganiselo othile wezinto ezixutywayo zongezwa kulwelo olutyhidiweyo lwe-aluminiyam (i-magnesium kunye ne-silicon zidla ngokudibaniswa kumnyango wenkqubo kunye nemigca yemveliso yefestile). I-slag kunye negesi yenkunkuma kwi-melt isuswe ngeendlela zokucoca ezihambelanayo.Ngaphantsi kweemeko zenkqubo yokuphonswa okufanelekileyo, ulwelo lwe-aluminium olunyibilikisiweyo lugalelwa kumatshini wokuphosa, lupholile kwaye luphonswe kwiintonga ezijikelezayo ezijikelezayo kunye neenkcukacha ezihlangabezana nokulindela.

2. I-Aluminiyam intonga extrusion

① Beka iintonga ze-aluminiyam tyaba kwi-rack yezinto eziphathekayo, thintela ukusondela kakhulu omnye komnye okanye uzipakishe, kwaye ugcine indawo ekhuselekileyo yokusebenza ukukhusela iintonga ze-aluminiyam ekuqengqelekeni okanye ukuwa.

②Fudumeza intonga ye-aluminiyam kunye nokungunda kwiziko ukunyusa ubushushu ukuya kwi-480 ° C, kwaye uyigcine ishushu iyure enye ngaphambi kokucubungula okulandelayo;

③Beka ukungunda kwisiseko sokufa se-extruder, faka intonga ye-aluminiyam kwindawo yokutya ye-extruder kwaye ulungiselele ukukhutshwa;

④Iprofayile ekhutshiweyo iphuma kumngxunya wokukhupha, kwaye intloko yesixhobo itsalwa yitrektara, kwaye ukusika kokuqala kwenziwa ngokobude obumiselweyo kunye nobukhulu.

3. Ukuqondisa

Iiprofayili ze-aluminium ezitsalwe yi-extrusion ngokuqhelekileyo azihlangabezani nemigangatho yokuqina, echaphazela ukusetyenziswa okulandelayo okanye ukusebenza kwisixhobo somatshini.Iiprofayili ze-aluminium ezikhutshiweyo zithunyelwa kwitheyibhile yokulungisa ukulungiswa, kwaye emva koko ihanjiswe kwindawo yemveliso egqityiweyo ukusika ubude.

4. Unyango lwangexesha

Ukubeka izinto zeprofayili ye-aluminium ye-alloy kwiziko lokuguga ukuze lifudumale kwiqondo elithile lobushushu kwaye ligcine lishushu kwiiyure ze-2-3 kunokuphucula kakhulu iimpawu ze-aluminium zeprofayili ye-alloy, ngokukodwa i-hardness properties.Beka iiprofayili ze-aluminium ezisikiweyo kwisakhelo sezinto eziphathekayo, uzithuthele kwindawo yokuguga, kwaye ungene kwiziko lokuguga ukwenzela unyango lokuguga. Xa ubushushu bokukhula bufikelela kwi-200℃, yigcine ishushu iiyure ezi-2, emva koko ulinde ukuba ikhululwe;Emva kokuba ukuguga kugqityiwe, inokukhutshwa kwi-oveni kwaye ungene kwinqanaba lokupholisa. Inokupholiswa ngokwemvelo okanye i-artificially kunye ne-cooler yomoya. Kweli nqanaba, umsebenzi we-extrusion uphela, kwaye i-extrusion yeeprofayili ze-aluminium kunye nomgangatho ofanelekileyo wembonakalo kunye nemilo kunye nobukhulu bugqityiwe.

5. Unyango lomphezulu

Faka unyango olufanelekileyo lwangaphezulu njengoko kufuneka. Okwangoku, kukho iinkqubo ezininzi ezidumileyo zonyango kumphezulu womnyango kunye neshishini lefestile: i-anodizing, i-electrophoresis, i-porcelain coating, isitshizi se-fluorocarbon, njl.

Qhagamshelana ne us ukubuza ngakumbi.

Umnxeba/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Ixesha lokuposa: Aug-31-2023