Iiprofayili ze-aluminium ze-T-slot zisetyenziswa ngokubanzi kwimizi-mveliso, izixhobo zoomatshini, kunye neenkqubo ezizenzekelayo ngenxa yamandla azo aphezulu, iipropathi ezikhaphukhaphu, kunye nokuguquguquka. Ngaba ufuna iprofayile ye-aluminium ehlala ixesha elide, yokusebenza okuphezulu kwe-T-slot yeprojekthi yakho elandelayo? Iinkonzo zethu ze-extrusion yesiko zibonelela ngokuguquguquka okungahambelaniyo kunye nomgangatho.

Uyilo kunye neNkqubo yokuKhulisa

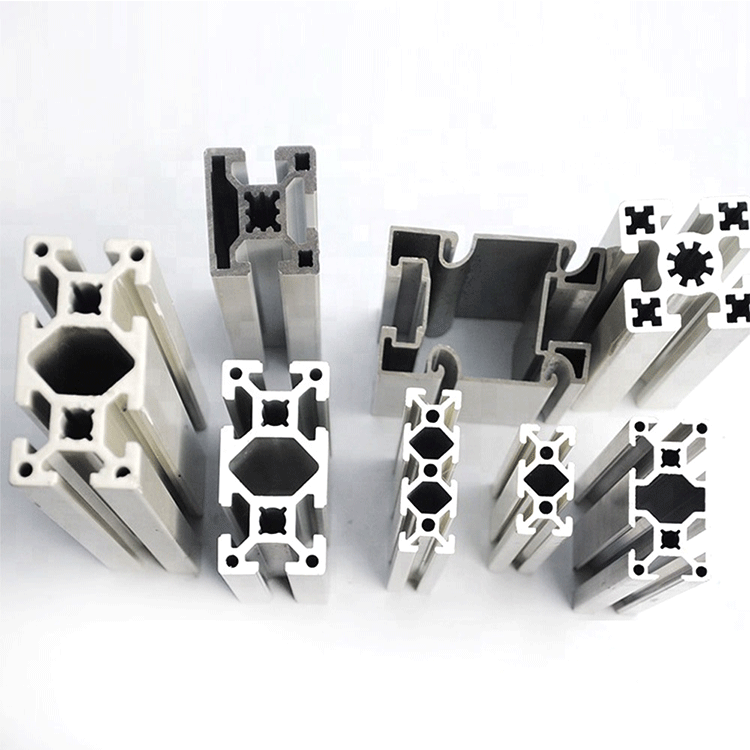

Iiprofayili ze-aluminium ze-T-slot zenziwe kwii-alloys ze-aluminium ezifana ne-6063-T5 okanye i-6061-T6 ngenkqubo ye-extrusion eshushu. Ngethuba lokukhupha, iibhilethi ze-aluminium zifudumala ukuya kwi-450-500 ° C kwaye zityhalwe ngesikhunta ukuze zenze iziqendu ezithile. Iimpawu eziphambili zeRuiqifeng ziquka:

- Ulawulo oluchanekileyo oluphezulu lwe-dimensional (ukunyamezela ngaphakathi kwe-± 0.1mm).

- Ukugqitywa komphezulu ogudileyo ukuze kube lula ukusetyenzwa emva kokulungiswa.

- Ulungelelwaniso lwamandla kunye nokuqina, okwenza kube ngokufanelekileyo kwizakhiwo zokuthwala umthwalo.

Unyango loMphezulu

Iiprofayili ze-aluminiyam ye-industrial ziphantsi konyango ukunyusa ukuxhathisa ukubola kunye nobuhle. Unyango oluqhelekileyo lomphezulu lubandakanya:

- Anodizing(ubukhulu be-oxidation ye-5-25μm, ukuphucula ukumelana nokunxiba).

- Powder Coating(ifumaneka ngemibala eyahlukeneyo).

- I-Electrophoretic Coating(ukuphucula ukuqina komphezulu kunye nokumelana nemozulu).

Usetyenziso lwe-T-slot yeeProfayili zeAluminiyam

Iiprofayili ze-aluminium ze-T-slot zisetyenziswa ngokubanzi kwi:

- I-Industrial Automation(ezifana nezakhelo zomgca wokuhlanganisa).

- Izixhobo zoomatshini(njengabagadi bomatshini kunye nezixhobo zokuvavanya).

- Izixhobo zombane(ezifana neekhabhathi kunye neeracks zeseva).

- Ishishini loKwakha(ezifana nezakhiwo ezixhasa udonga lwamakhethini).

Iindlela zoQhagamshelwano lweProfayili yeAluminiyam

Iiprofayili zeAluminiyam zibonelela ngeendlela ezahlukeneyo zokunxibelelana, ngokuqhelekileyo zisebenzisa izixhobo ezikhethekileyo ngaphandle kwesidingo se-welding. Oku kuzenza zikhuseleke ngokusingqongileyo kwaye kube lula ukuzidibanisa, ukuqhawula, ukuthutha, nokufuduswa kwenye indawo. Kuyilo lwesiko, iiprofayili ze-aluminium zisetyenziswa kakhulu.

Nazi iindlela ezingama-20 zoqhagamshelwano eziqhelekileyo:

- Isidibanisi esakhelwe ngaphakathi: Isetyenziselwa ukudibanisa kwe-90 ° phakathi kweeprofayili ezimbini; uxhulumaniso olufihlakeleyo olunamandla aphezulu.

- Izibiyeli zeKona (90°, 45°, 135°): Isetyenziselwa ukudibanisa i-angle yangaphandle kwi-90 °, 45 °, kunye ne-135 °; inokukhusela izinamathiselo zepaneli.

- Connection Screw: Isetyenziselwa ukudibanisa kwe-90 ° yangaphakathi; kulula ukuyifaka kunye nokususa, esetyenziswa ngokuqhelekileyo kwiindawo ezivaliweyo ezilula.

- Isiqhagamshelanisi seSilothi esimile okwe-L (90°): Isetyenziselwa ukudibanisa kwe-90 °; kulula ukuyifaka kwaye ayifuni umatshini owongezelelweyo.

- Isiqhagamsheli seSilothi esiPhezulu (45°): Isetyenziselwa ukudibanisa kwe-45 ° slot; yomelele kwaye isetyenziswa ngokuqhelekileyo kwiifreyimu zeminyango.

- Qeda isidibanisi sobuso: Isetyenziselwa udibaniso lwe-engile ekunene phakathi kweeprofayili ezimbini okanye ezintathu; iqinile kwaye iyathandeka ngobuhle.

- Isidibanisi se-3D (iEngile yasekunene): Isetyenziselwa udibaniso lwe-engile ekunene phakathi kweenkangeleko ezintathu; ngokukhawuleza kwaye kulula.

- Isidibanisi se-3D (Iengile e-R): Isetyenziselwa uqhagamshelo lwe-engile yasekunene phakathi kweenkangeleko ezigoso ezintathu; ngokukhawuleza kwaye kulula.

- Ikliphu ye-Elastic: Isetyenziselwa ukudibanisa kwe-90 ° yangaphakathi; kulula ukuyifaka kunye nokususa.

- Qeda isiqhagamshelo: Isetyenziselwa ukudibanisa kwe-90 ° yangaphakathi; efihliweyo kunye namandla aphezulu.

- Isidibanisi esithe ngqo: Isetyenziselwa uxhulumaniso lwangaphakathi lwamandla aphezulu phakathi kweeprofayili ezimbini.

- Isidibanisi se-Anchor: Isetyenziselwa udibaniso lweprofayili kunye neenketho ezininzi ze-engile; ifihliwe kwaye ifanelekile.

- Ihinge ehlengahlengiswayo: Isetyenziselwa ukudibanisa iprofayili, ilungelelanise phakathi kwe-30 ° -150 °.

- I-Rotary Connection Plate: Isetyenziselwa ukudityaniswa kweeprofayili ezahlukeneyo kunye nokujikeleza kwee-engile ezininzi.

- Icwecwe loQhagamshelwano: Isetyenziselwa uqhagamshelo lweprofayile ezininzi; amandla aphezulu kwaye akukho machining ongezelelweyo.

- Rotary Corner Bracket: Ivumela uxhulumaniso kuyo nayiphi na iengile.

- INdibano yeNtloko yeBolt: Faka amantongomane e-elastiki kwiprofayili enye kunye neposti engqukuva kwenye, ekhuselekile ngebholithi.

- Ipleyiti yoQhagamshelwano lwaNgaphandle emise okweNxweme: Isetyenziselwa amandla aphezulu "+" uqhagamshelwano lwesakhiwo.

- Uhlobo lwe-L, i-T-Type yePlayiti yoQhagamshelwano lwaNgaphandle: Isetyenziselwa amandla aphezulu "L" okanye "T" uqhagamshelwano lwesakhiwo.

- I-Y-Type ipleyiti yoQhagamshelwano lwaNgaphandle: Isetyenziselwa amandla aphezulu "-" uqhagamshelwano lwesakhiwo.

Ezi ndlela zokudibanisa zingabonakaliswa ngemizobo e-animated, okwenza kube lula kwiinjineli ukuba zikhethe ezona zisombululo zoqhagamshelwano ezifanelekileyo ngexesha lenkqubo yoyilo.

Ixesha lokuposa: Feb-28-2025