I-Aluminiyam extrusion yinkqubo yokwenziwa esebenza kakuhle kakhulu kwaye eguquguqukayo esetyenziselwa ukwenza amacandelo aneeprofayili ezinqamlezayo. Embindini wale nkqubo kukho enye yezona zinto zibalulekileyo:i-extrusion iyafa. Esi sixhobo sobunjineli obuchanekileyo sibumba ialuminiyam phantsi koxinzelelo olukhulu kwaye sidlala indima ebalulekileyo ekumiseleni umgangatho wemveliso, ukugqitywa komphezulu, kunye nokuchaneka komda.

Yintoni iAluminiyam Extrusion Die?

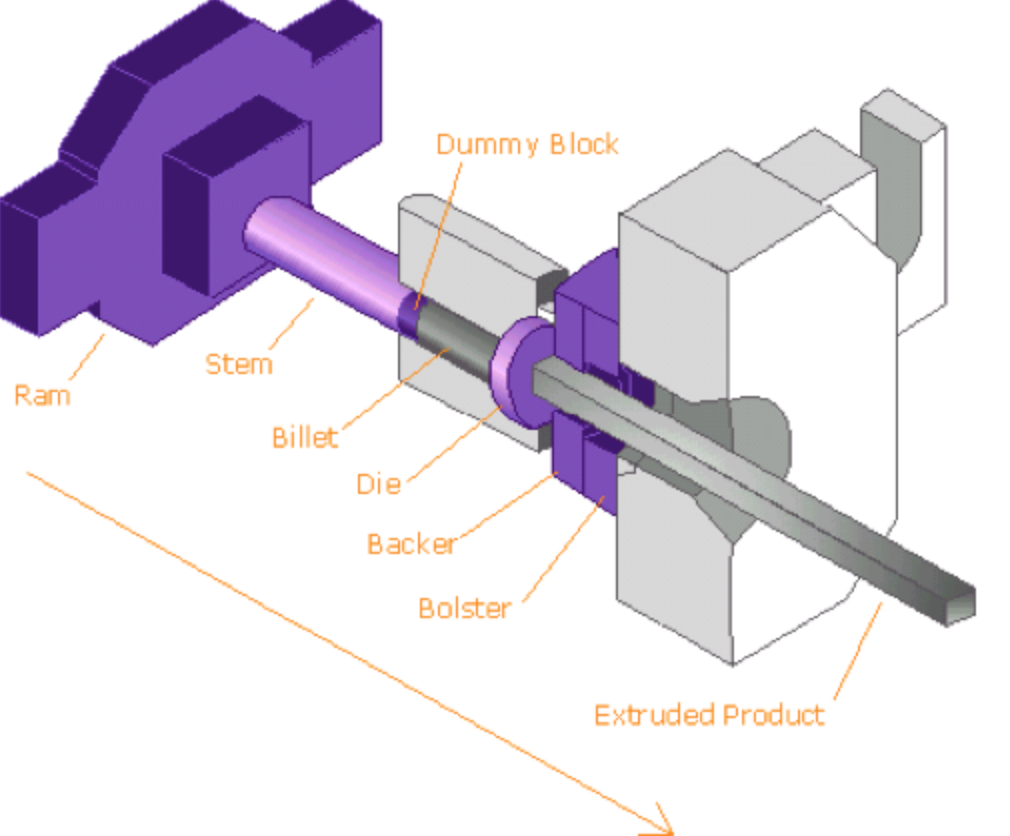

I-extrusion die sisixhobo sentsimbi esilungiselelwe ngokukodwafa ukuvulaebumba ialuminiyam njengoko inyanzeliswa phantsi koxinzelelo oluphezulu. Kanye kunye nezixhobo zenkxaso ezifana ne-backers, i-bolster, kunye ne-sub-bolster, i-die iqinisekisa ukulungelelaniswa okufanelekileyo kunye nokunyaniseka kwesakhiwo ngexesha lokukhupha.

Iintlobo ze-Extrusion ziyafa

Ukufa kwe-Extrusion kwahlulwa ngokweendidi ezintathu eziphambili ngokusekwe kwijiyometri yeprofayile efunekayo:

1. Ukufa okuqinileyo

Isetyenziselwa ukuvelisa iinkangeleko ngaphandle kwemingxuma - efana neebha, iiengile, okanye amajelo.

● Amacandelo:

○ Icwecwe lokufa: Iqulethe i-orifice emile yeprofayile yokugqibela.

○I-Backer Plate: Ibonelela ngenkxaso emva kwefa.

○Ipleyiti yesondlo (ukhetho): Incedisa ekukhokeleni ukuhamba kwezinto.

2. Umngxuma Ufa

Yenzelwe iiprofayili ezine-voids yangaphakathi njengetyhubhu okanye iifreyimu zefestile.

●Amacandelo:

○Mandrel (okanye core): Yenza umngxuma wangaphakathi.

○Die Cap: Yenza imilo yangaphandle kwaye ibambe i-mandrel kwindawo.

○Umxhasi: Ibonelela ngenkxaso yesakhiwo kunye nolawulo lobushushu.

3. Semi-Hollow Dies

Isetyenziselwa iiprofayili ezine-voids evaliweyo - ukudibanisa iimpawu zamacandelo aqinileyo kunye angenanto. Ezi zilungele iijometri ezintsonkothileyo ezinobunzima obuguquguqukayo beendonga.

Inkqubo ye-Extrusion kunye noMsebenzi weDie

Amanyathelo aphambili e-extrusion abandakanya:

1.Billet Preheating:

Iibhiliti ze-aluminium zifudumeza ukuya kwi-370-500 ° C (700-930 ° F) ukuphucula iplastiki.

2.Iyalayisha kunye nokuKhulisa:

Ibillet ilayishwa kwisikhongozeli, kwaye inkunzi ye-hydraulic (ngoxinzelelo olusuka kwi-1,000 ukuya kwi-15,000 yeetoni) iyityhalela kwidayisi.

3.Ulwakhiwo lweProfayili:

I-aluminium ithatha imilo yokuvula i-die njengoko iphuma, yenza iprofayili efunekayo.

4.Ukupholisa, ukusika kunye nokugqiba:

Iiprofayili ziyapholiswa, zolulwe, zisikwe ubude, kwaye zinokugqitywa umphezulu njenge-anodizing okanye umgubo wokugquma.

Kuyo yonke le nkqubo,i-die iqinisekisa ukuchaneka kwemilo, umgangatho womphezulu, kunye nokuhambelana.

Unyamezelo oluNxulumene ne-Die kunye noLawulo lokutyeba kweendonga

Ukuchaneka kubalulekile. Ukunyamezela kwe-aluminium extrusion kuxhomekeke koku:

●Ubungakanani beprofayile kunye nobunzima

●Ubunzima bodonga(iindonga ezibhityileyo zonyusa ubunzima)

●Yifa unxibe ngokuhamba kwexesha

●Ubunzima bodongazinokwahluka kancinci, ngakumbi xa kusweleka okutsha - i-extrusions yokuqala inokuba bhityile kancinci, kodwa ngokusetyenziswa, ifa uzinzo kwaye ihambelane ngcono noyilo lwegama. Kungenxa yoko le ntoiibhetshi ezilandelayoNgokuqhelekileyo zibonisa iziphumo ezityebileyo kunye nezihambelanayo.

Ukunyamezelana okuqhelekileyo kulawulwa yimigangatho yamazwe ngamazwe njengeEN 755-9okanyeI-AA (uMbutho weAluminiyam)iinkcukacha.

Die Surface Treatments and Maintenance

Ukuphucula ukusebenza kunye nobomi, i-extrusion iyafa ihlala iqhubeka:

Nitriding

Inkqubo yokuqina komphezulu esasaza initrogen kumphezulu wokufa, inyusa ubulukhuni kunye nokumelana nokunxiba - kubalulekile ekuphatheni uxinzelelo oluphezulu kunye nobushushu.

Die Preheating (Die Cooking)

Kwaziwa njenge "煲模(bao mo)” NgesiTshayina, olu qheliselo lufudumeza ngokuthe ngcembe ifa ngaphambi kokuba lukhutshwe ukuze lunciphise ukothuka kwe-thermal kunye nokuphucula ukuhamba kwentsimbi.

Imiceli mngeni yokuFa eqhelekileyo kunye neZiqhelo zoKhuselo

✅ Ukunxiba kunye nokukrazula

Uxinzelelo oluphezulu kunye nobushushu bubangela ukunxiba kancinci.Ukuhlolwa rhoqo, ukupholisha kwakhona, kunye nokuphinda kufakwe i-nitridingukwandisa ubomi bokufa.

✅ Iziphene zoMphezulu

Imikrwelo, imigca yokufa, okanye ukwakhiwa kunokuchaphazela umgangatho womphezulu. Inkquboukucoca kufakwayeunyango olungaphezuluukunceda ukunciphisa iziphene.

✅ Ulawulo lweThermal

Ukufudumeza okungalinganiyo okanye ukupholisa kukhokelela kwiziphene okanye ukophuka. Ukugquma okufanelekileyo kunye nokushisa kwangaphambili okulawulwayo kubalulekile.

✅ Ulungelelwaniso kunye neNkxaso

Ulungelelwaniso olulambathayo lubangela iimpazamo ezinobungakanani kunye nokusilela kwangoko. Ngamaxesha athileulungelelwaniso kwakhonakwayeukugcinwazibalulekile ukuchaneka.

Kutheni kufa okubalulekileyo kwiAluminiyam Extrusion

I-extrusion eyilwe kakuhle, egcinwe kakuhle iyafa inefuthe elithe ngqo:

●Ukuchaneka komgangatho

●Ukuntsokotha kweprofayile

●Isantya sokukhupha

●Ukugqitywa komphezulu

●Iindleko zemveliso zizonke kunye nokuhambelana

Ukukhetha uhlobo lokufa oluchanekileyo, ukuqonda ulawulo lobunzima bodonga, kunye nokuphumeza izenzo zokukhusela ezikhuselekileyo zokukhusela zibalulekile ekufezekiseni okufanayo, iziphumo eziphezulu.

Ngaba ujonge iFane elithembekileyo leSiko kunye neFanethi ye-Extrusion?

E [Igama leNkampani yakho], sisebenza ngokukhethekileyo kwi-extrusion ye-aluminium echanekileyo kwaye sinikezela ngenkxaso epheleleyouphuhliso lwesiko lokufa, ukwenza iprofayile, kwayekufa ulawulo lomjikelo wobomi. Nokuba uvelisa iiprofayili eziqinileyo, ezingenanto, okanye ezintsonkothileyo ezixubileyo, iqela lethu lobunjineli likulungele ukunceda ngeengcaphephe zemibono kunye nemveliso ethembekileyo.

Qhagamshelana nathi namhlanjeukufunda ngakumbi malunga nendlela esinokuzisa ngayo uyilo lwakho ebomini kunye nezisombululo ezifanelekileyo ze-extrusion.

I-imeyile: will.liu@aluminiyam-artist.com

Iwebhusayithi: www.aluminiyam-artist.com

Idilesi:Indawo yoShishino yasePingguo, kwisiXeko saseBaise, eGuangxi, eChina

Ixesha lokuposa: Jun-17-2025